In our highly-equipped testing labs focus on the following areas: Alarm systems, automotive/e-mobility, components, electric smog measurements, household and leisure products, industrial products, information technology, laboratory products, lights, medical devices, motor vehicle accessories/parts, railway technology products.

Testing is carried out by experts in our state-of-the-art laboratories or, in many cases, conveniently on-site. Our EMC testing regime takes these standards into account, issuing certification for compliance with international market regulations. Anybody wanting to bring such products onto the European market has to comply with the EMC directive 2014/30/EU. To prevent this, electric and electronic devices have to adhere to electromagnetic compatibility (EMC) guidelines and must bear the CE marking. Electromagnetic interference and susceptibility that is merely annoying in one context can be life-threatening in another.

Electromagnetic compatibility testing download#

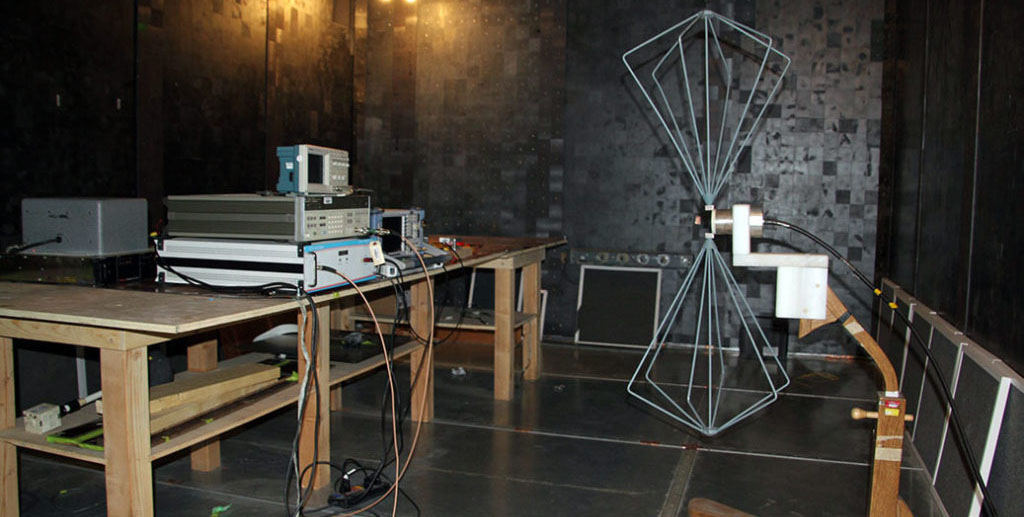

Narrow down on EMC Test Equipment based on specification, view product details, download datasheets and get quotes on products that meet your requirement.Manufacturers of electric and electronic devices in a wide range of industries, from automotive and railway to household and leisure goods to medical and laboratory equipment want to ensure that their products function safely and effectively. These kits provide EMC antennas, current probes, measurement cable, comb generator, and other accessories needed for conducting the EMC testing.Įverything RF has listed EMC Test Equipment from the leading manufacturers. EMC antenna kits are used to conduct radiated emission & immunity test in OATS. Types of EMC antenna are – monopole, dipole, biconical, log-periodic, horn, loop, active antenna, array antenna, blade, biological, spiral, and yagi antenna. It is also used to check the electric field uniformity during the EMC immunity tests, and to diagnose and repair EMI problems that very often arise during the early stages of the product development cycle.ĮMC Antennas can be used to conduct the EMC testing (both emission & immunity test) in screened/anechoic rooms and open area test site (OATS). The most stringent requirements in this field apply to vehicles and equipment. This is used along with transducers (For example, antenna, near field probes (E/ H field probe), etc.) to measure the radiated and conducted EMI emissions from electronic devices. Electromagnetic compatibility (EMC) compliance is a regulatory requirement. They are primarily used for EMC radiated emissions testing.Īn EMI Receiver is a measuring tool to observe RF power levels. EMC equipment is designed to comply with both EMC emission and immunity standards such as FCC, CISPR, EN, BS, VDE, VG, FAA, and MIL-STD.ĮMC preamplifiers are RF amplifiers that convert a weak signal into a stronger output signal that is noise-tolerant and strong enough to be sent to an EMI receiver. A product should have EMC certifications in order to get into the market.ĮMC tests are conducted using equipment such as E-field generators, EMC antennas, EMC power amplifiers, EMC power meters, EMC preamplifiers, EMI receivers, current probes & near field probes, EMF meters, and other supporting equipment. If the product complies with the EMC standards, it will not emit intolerable EMI (so the product does not disturb nearby devices), and it can withstand the EMI emitted from nearby devices (so the product work normally in the EMI environment). Electromagnetic compatibility (EMC) testing is conducted to verify whether the electrical and electronics product complies with EMC standards.

0 kommentar(er)

0 kommentar(er)